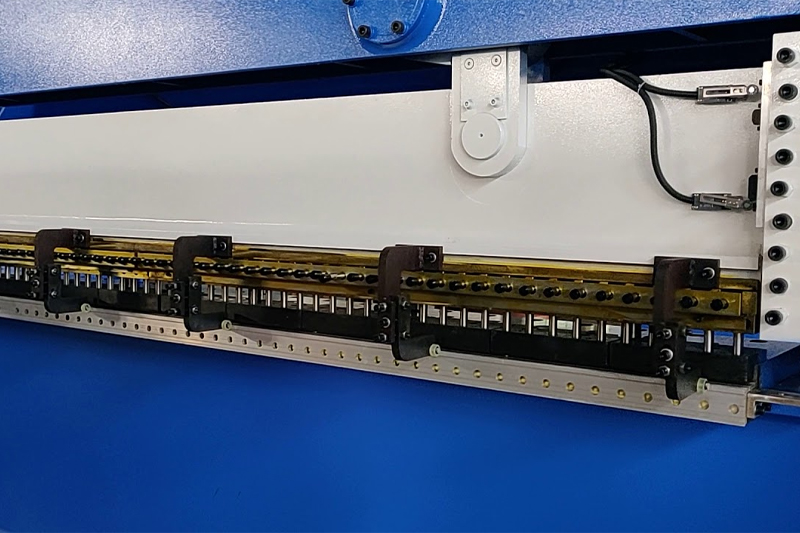

Hole Punching Machine

The Hole Punching Machine is a versatile and essential tool in various manufacturing and processing industries. The machine is used to punch holes into various materials, which is crucial for applications such as assembly, labeling, and part fabrication. It helps in creating precise holes for bolts, screws, and other fasteners, or for producing perforations in materials.

Commonly used in industries like metalworking, woodworking, plastics, packaging, and paper processing. It's essential for applications in manufacturing, construction, and office work.

- Enhanced Efficiency: Automates the punching process, increasing productivity and reducing manual effort.

- Consistent Quality: Provides uniform hole size and placement, ensuring high-quality output.

- Flexibility: Accommodates various materials and hole shapes, making it suitable for diverse applications.

- Cost-Effectiveness: Reduces labor costs and material waste, contributing to lower production costs.

- Precision: Ensures accurate hole placement and size, crucial for applications that require high precision.

- Versatility: Capable of punching different shapes and sizes of holes, providing flexibility for various applications.

- Durability: Built with robust materials to withstand frequent use and heavy-duty operations.

- Efficiency: Designed to minimize waste and optimize material usage, contributing to cost-effective production.

- Ease of Maintenance: Includes features for straightforward cleaning and maintenance, ensuring long-term reliability and minimal downtime.